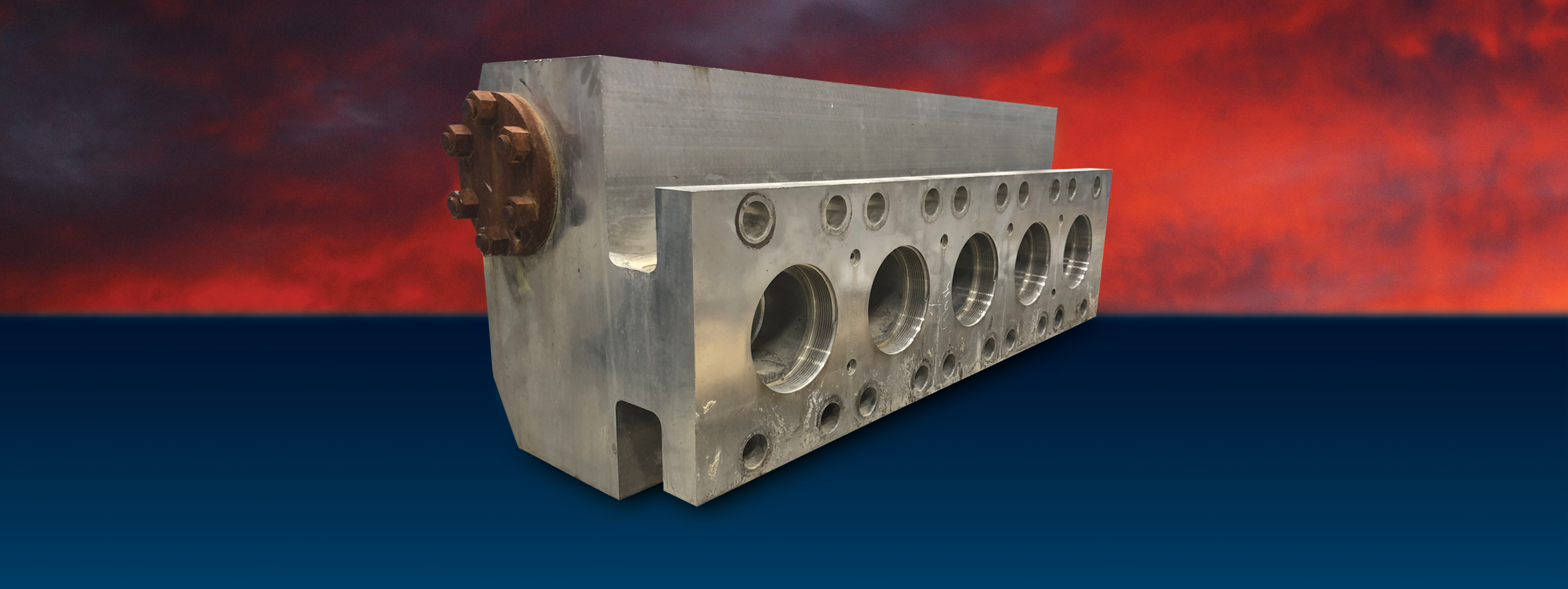

FLUID END REFURBISHMENTS

CS&P’s fluid end inspection and repair services allow customers to restore fluid ends that have been removed from service for wash-outs and other internal damage. Our proven technology has been extensively field tested and provides significant extended service life for fluid ends. Our process allows customers to preserve existing plunger size or in some cases increase to a larger plunger diameter.

Benefits:

• Extends Fluid End Service Life by 500-600 Hours

• Proprietary Sleeving Process

• Reduces Overall Fluid End Capital Expenditure

Process:

• 100% Evaluation of Failed Fluid End

• Identification of all Internal Damage to Include:

• Bore Washouts

• Thread Damage

• Internal Surface Damage

• Recommended Repair Scope and Quote

• Customer Approval and Completion of Workscope